Feature

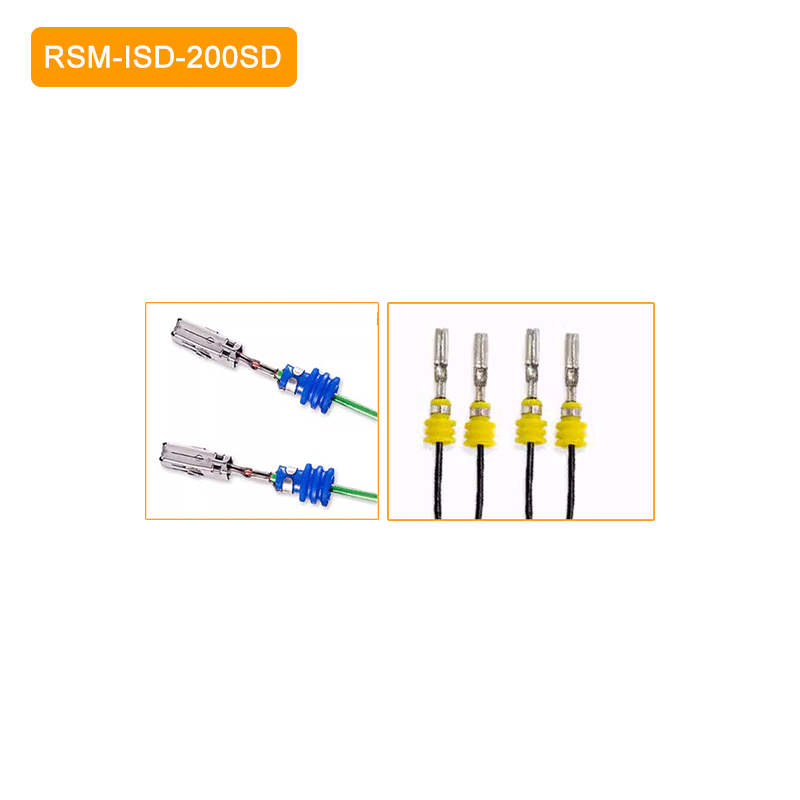

- Highly efficient. 2 wires are processed at the same time and seal insertion, wire stripping and wire crimping are combined into one.

- Forcible seal insertion and flexible seal insertion methods are optional, which can work for different scenes that require high installation speed or high installation accuracy.

- Adopt servo motor to guarantee high-speed and stable crimping.

- Seal applicator/track design for easier and quick changeover, meeting as many needs as possible.

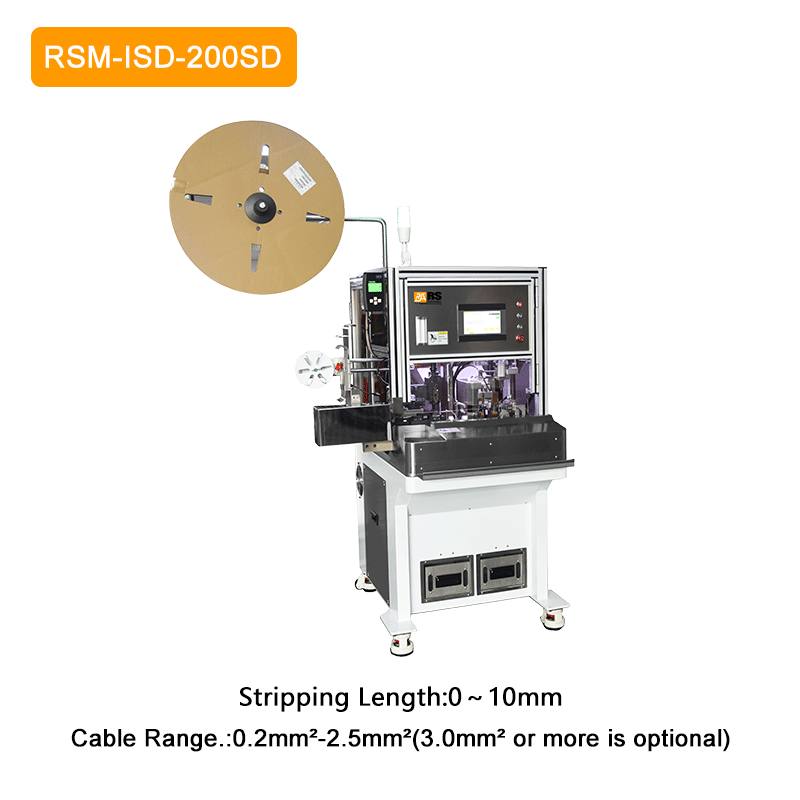

- Accurate stripping length guaranteed by combination of motor and lead screw.

- Recipes can be stored for convenient and rapid processing of multiple types of wires.

- The intuitive software with touch screen controls is user friendly and allows the stripping length, cut depth, seal insertion depth and crimping position to be saved.

- 3 work stations of seal insertion, wire stripping and wire crimping can be controlled separately, easier for machine adjustment and troubleshooting.

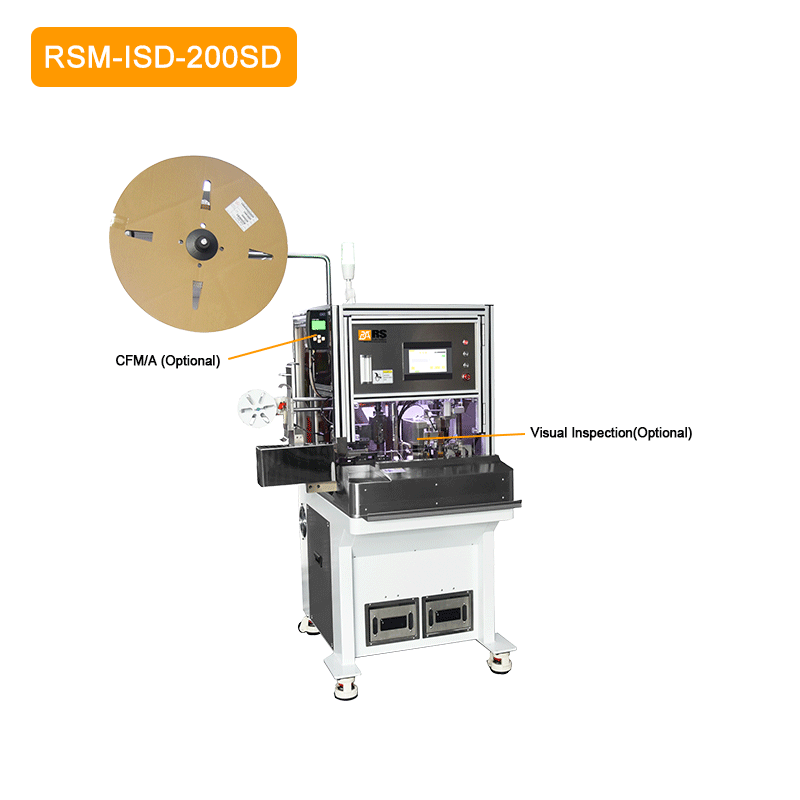

- Other options are also possible: CFA/M with data acquisition and visual inspection cameras.